Blog / Electric motor

Posted on 8 June 2013 at 11:37 pm (CET)

Category: Electric motor

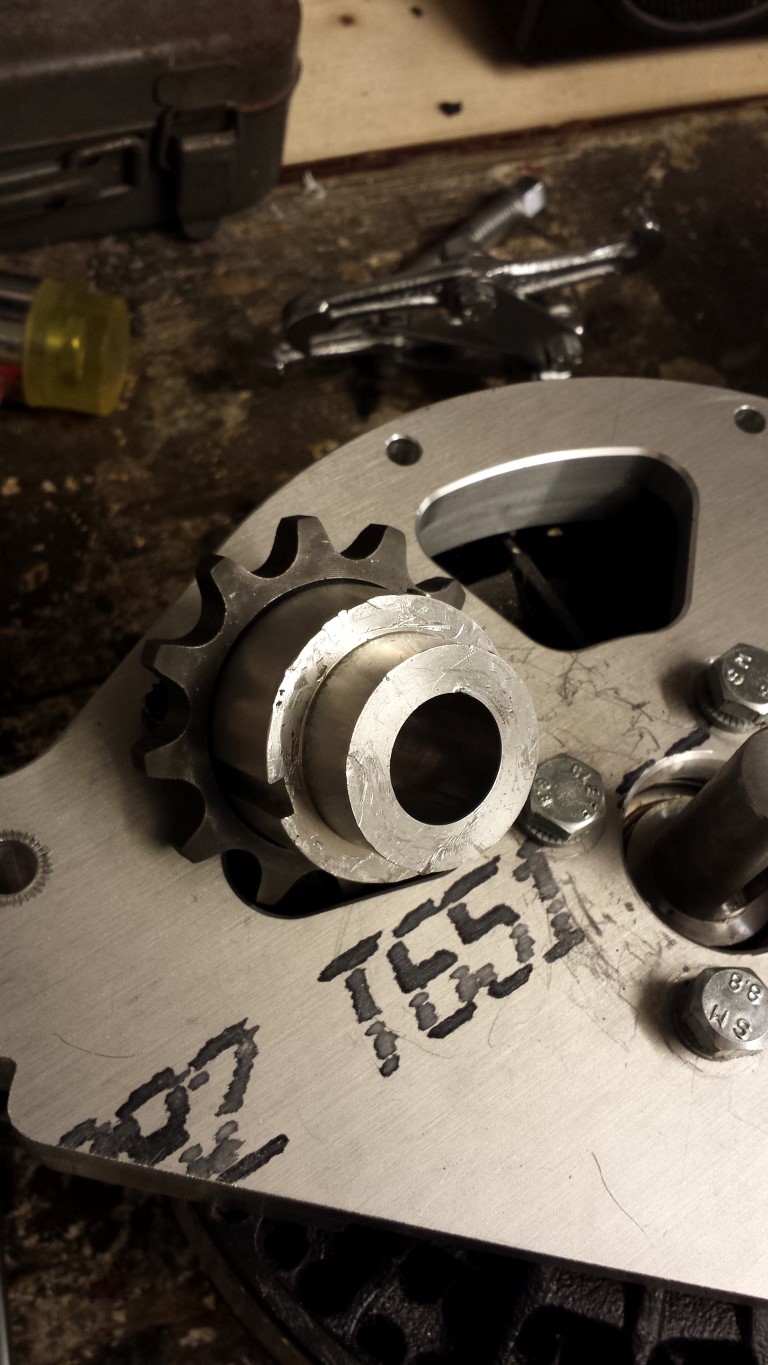

Was busy making a small plate for the RPM sensor, had to remove the adaptor with sprocket from the motor for this. But I couldn't get it off, seemed to be stuck somewhere while the set screw was loose. So I went to buy a set of disk pullers to still be able to take it off. After 2 hours and 2 broken disk pullers I finally managed to take the adaptor off. But what I saw next didn't really make me happy. The axle was damaged by the set screw that's in the adaptor.

I think this happened because the set screw was tightened and after that I tightened the bolt on the sprocket. This also moved the whole adaptor and so this is the consequence. Partly my own mistake ofcourse but also the design with the set screw not working well. Wasn't my own idea anyway, I wanted to do it differently.

The adaptor itself is badly damaged as well by all the attempts to get it off with the disk pullers. Didn't mind it that much, was more important that the motor would not get damaged.

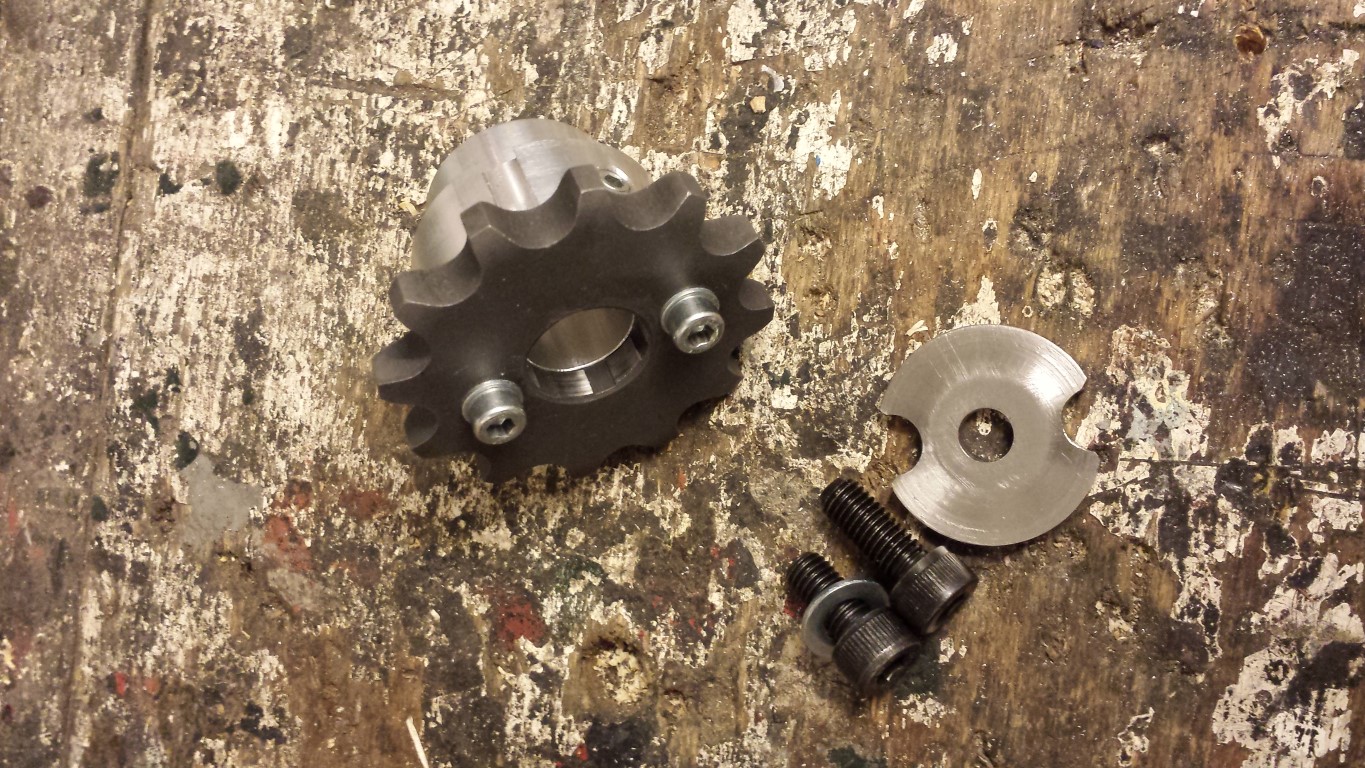

I now want to have a new adaptor made that exactly matches my own idea. It'll have a keyway so I can just place a key between the axle and adaptor. A lot better and stronger that way. The sprocket will be attached the same way though. It will also get the exact size needed so that no set screw will be necessary. The bolt on the sprocket will keep it attached on the axle.

I checked if I could repair the axle a bit and it went pretty well with a fine grinding stone and some fine grit sandpaper. It'll ofcourse never be as new anymore but I don't think I could get it any better than this.

Now I have to wait again for the new adaptor. Meanwhile I can already start on the battery boxes though. Only having some trouble with plastic welding so I'll glue the insides first and maybe after that I'll still weld the outsides.

Posted on 23 May 2013 at 11:35 pm (CET)

Posted on 23 May 2013 at 11:35 pm (CET)

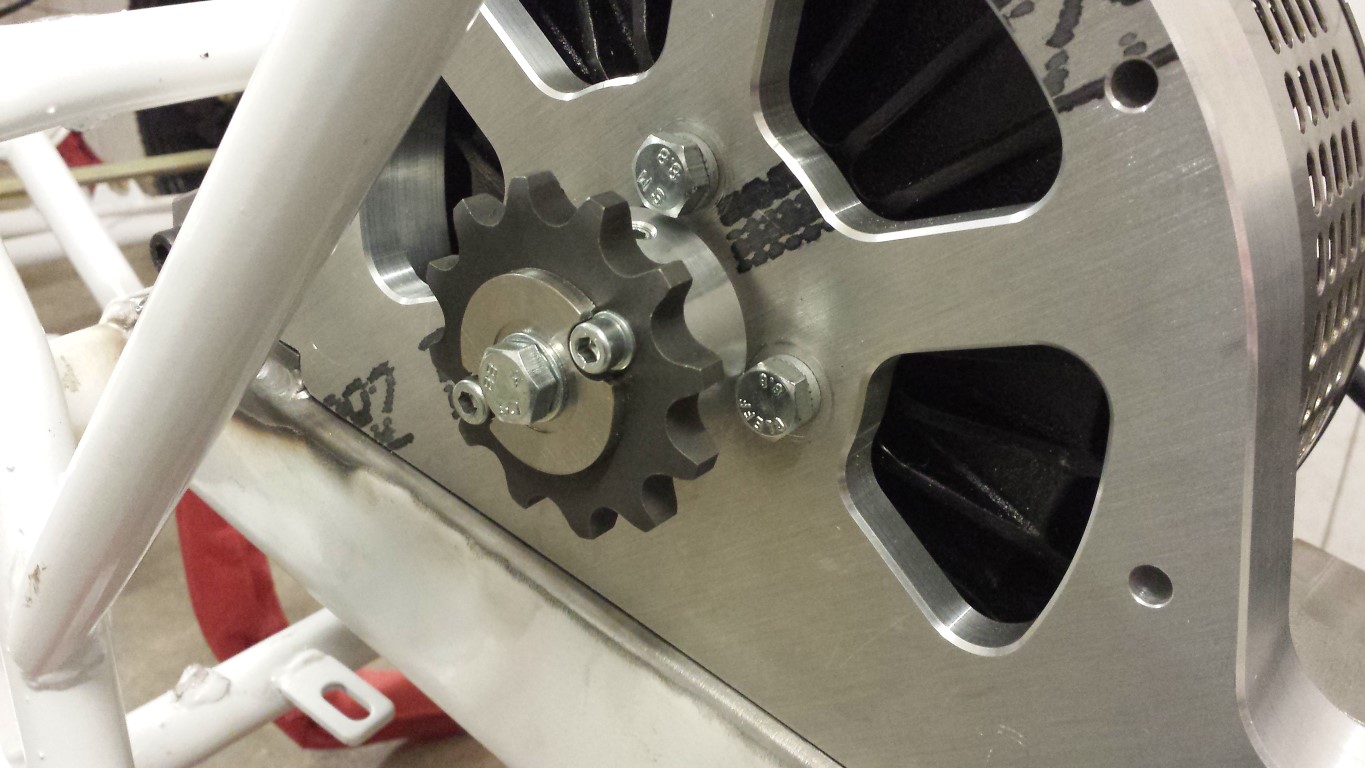

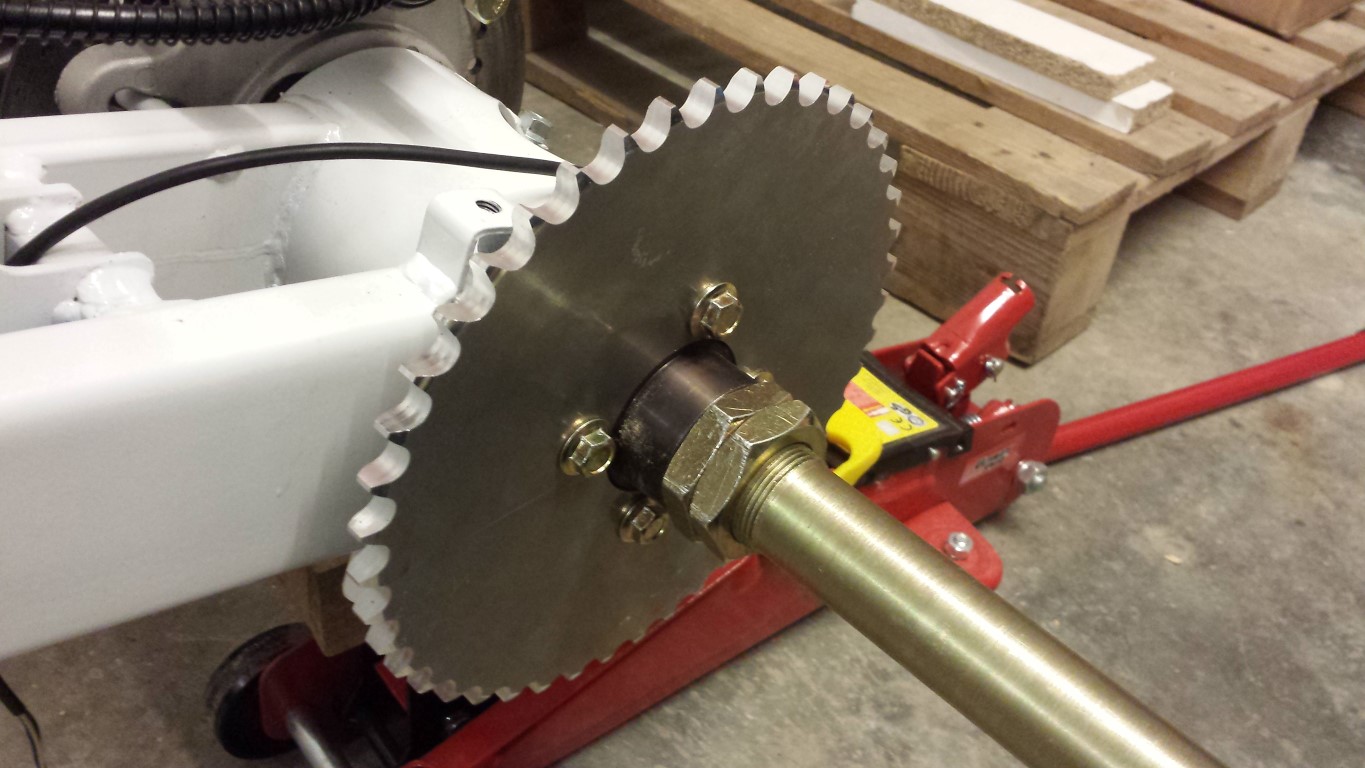

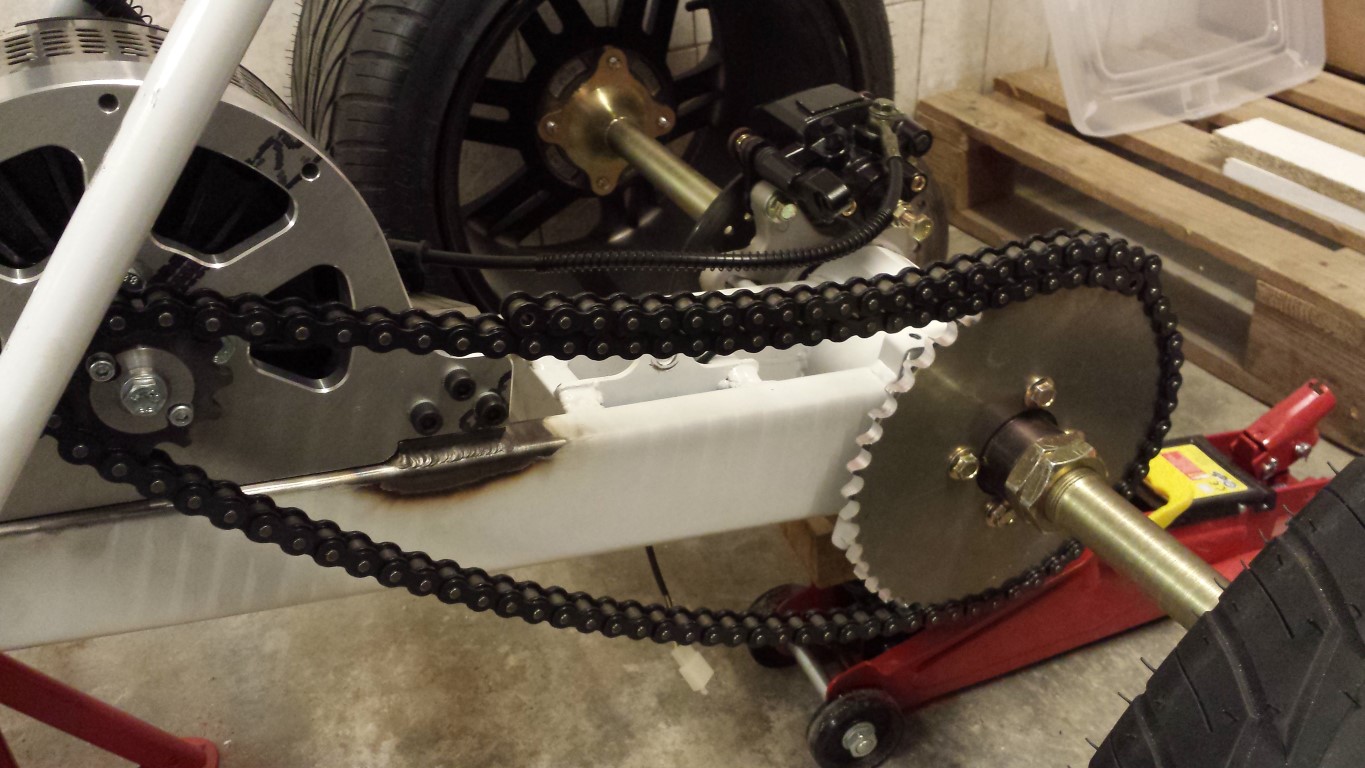

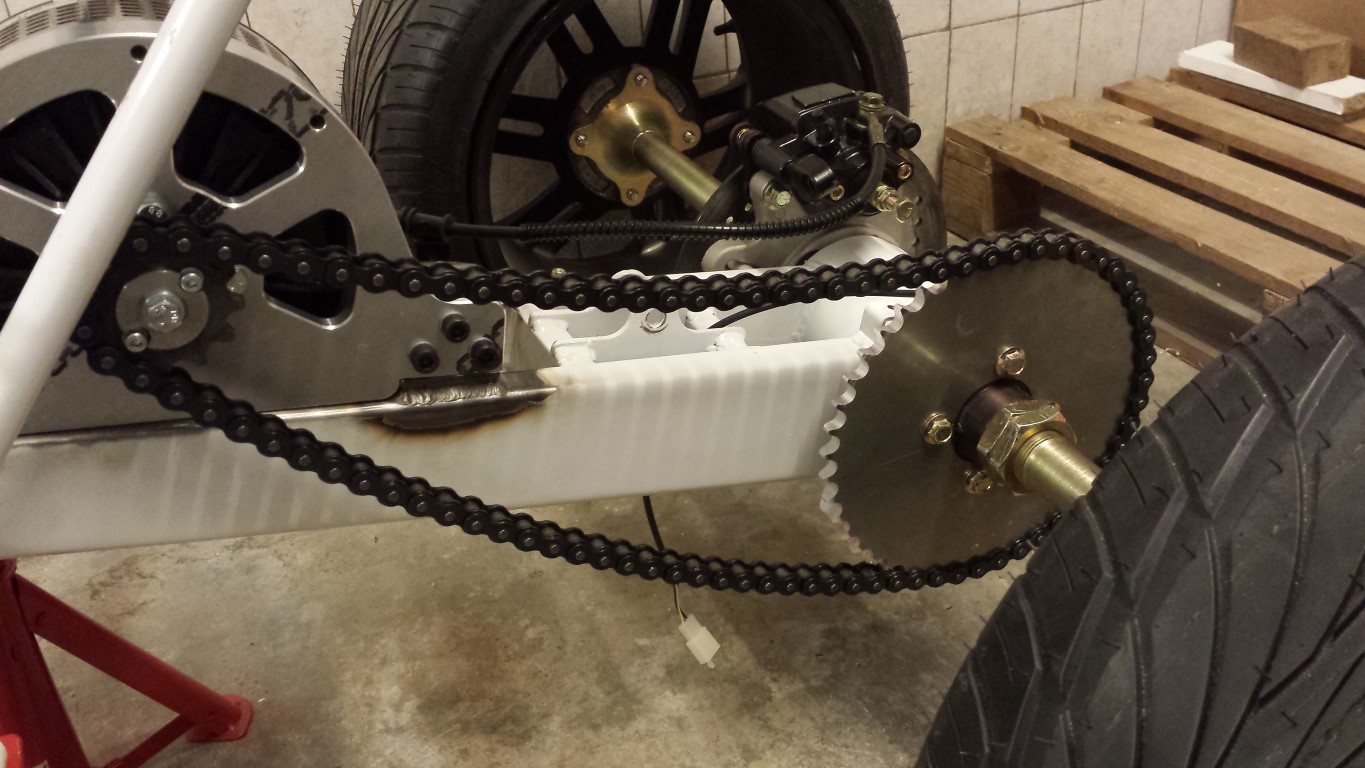

Today I was able to continue building. I received the adaptor and sprockets. They all fit perfectly.

Also checked how the chain would fit. Could shorten it quite a bit.

Took a while to shorten it since I don't have the tools for this but I succeeded anyway.

Now it just needs some more tension but it was getting a bit late already so I'll do this tomorrow. Could be that I still have to take 1 link out, not really sure if I still had the bearing house in the front position. It has quite a bit of play right now. But from what I can tell the chain is sitting in a straight line, didn't even have to adjust the adaptor. It just sits all the way on the axle.

Posted on 22 May 2013 at 12:14 am (CET)

Posted on 22 May 2013 at 12:14 am (CET)

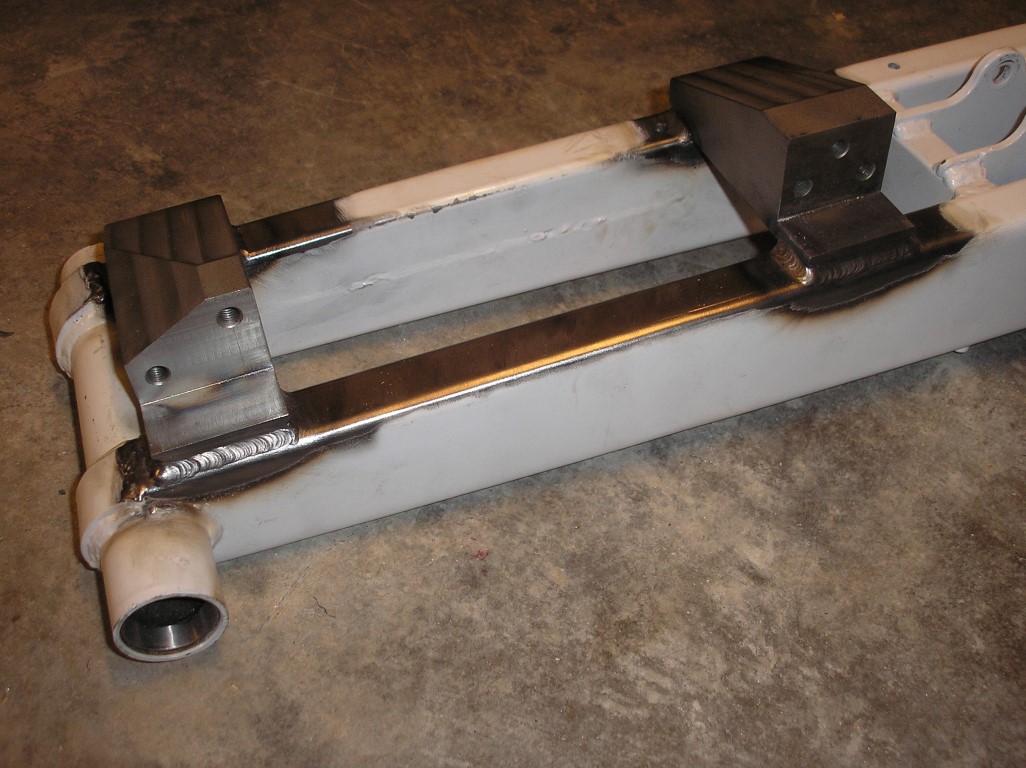

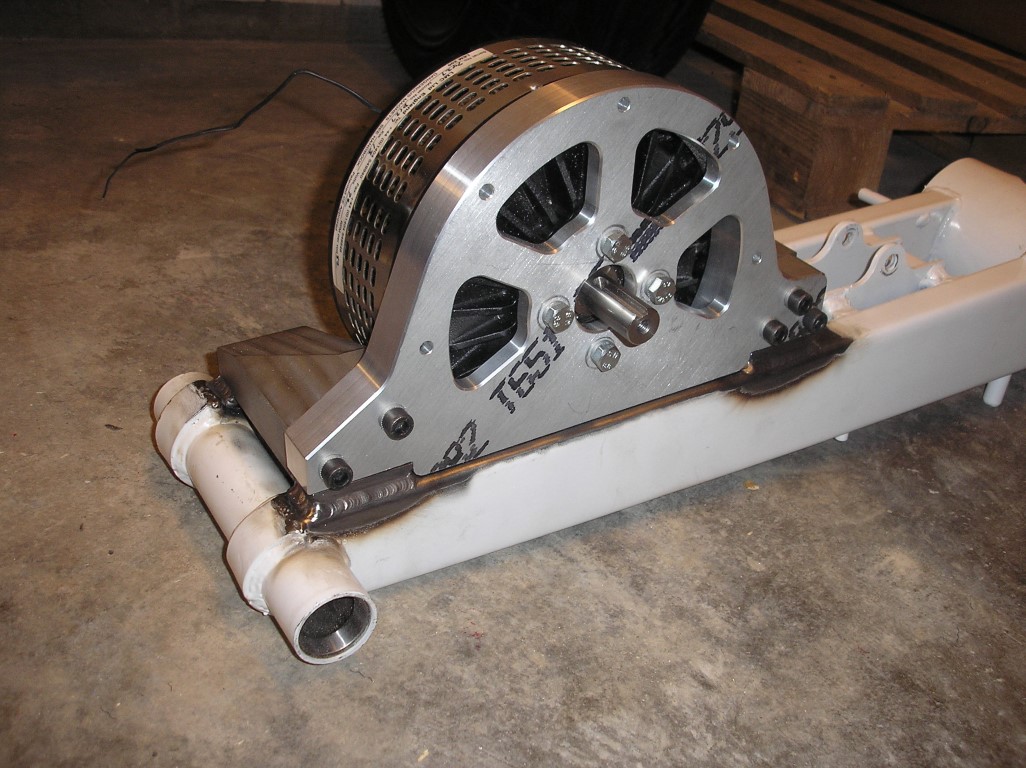

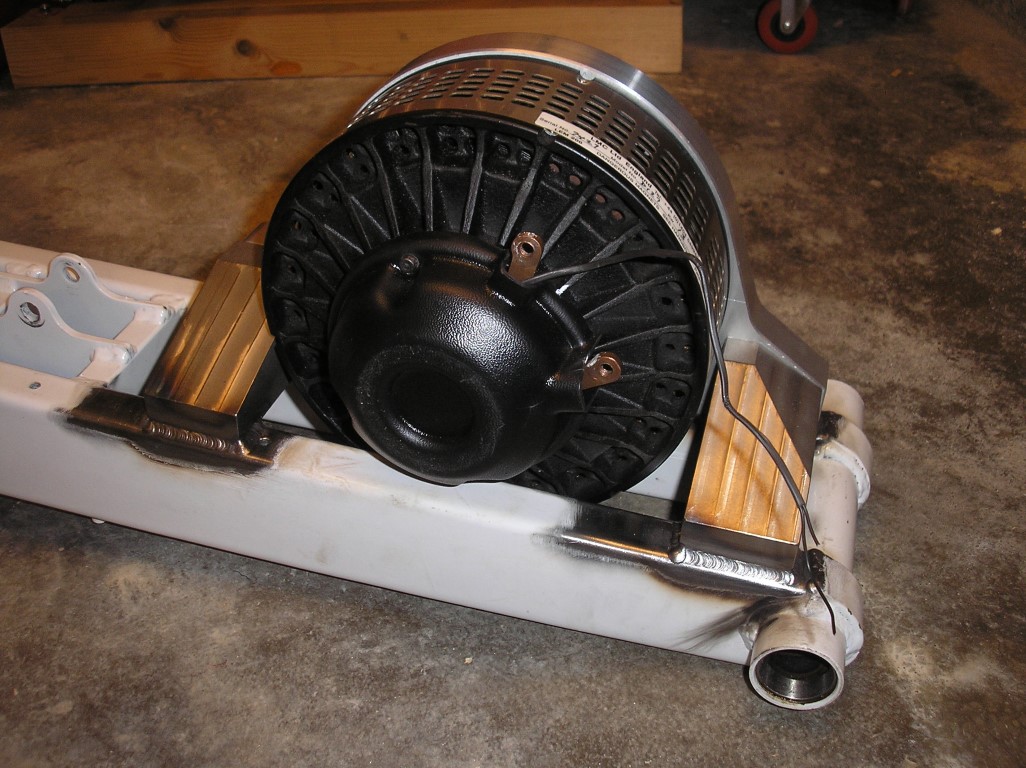

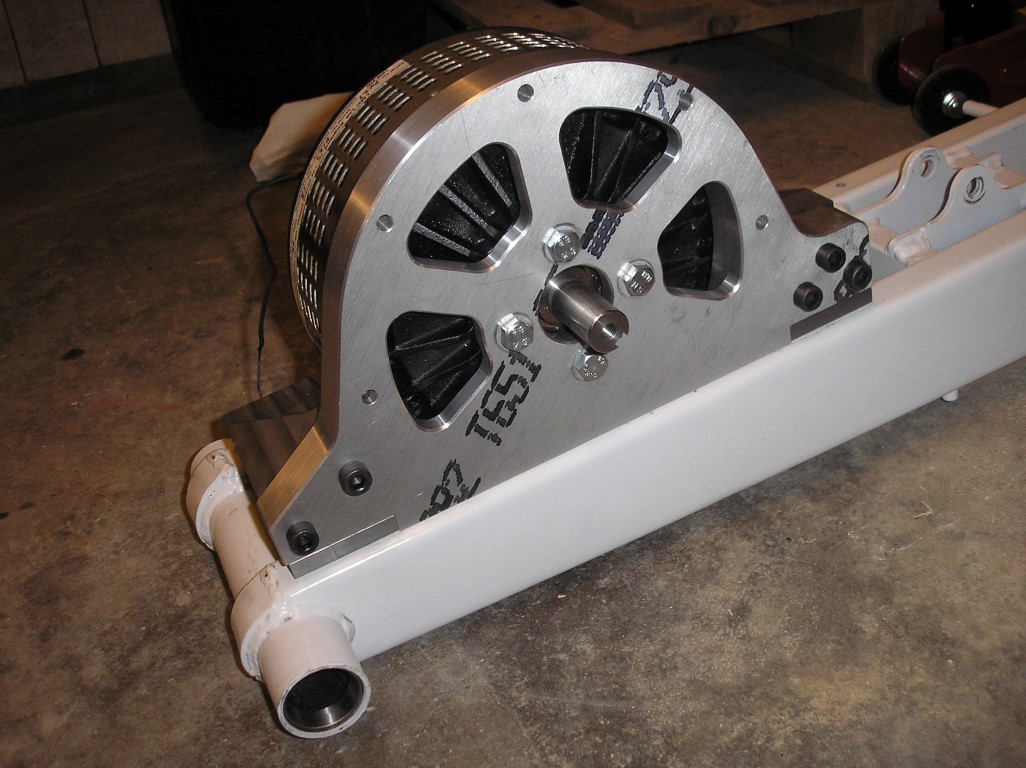

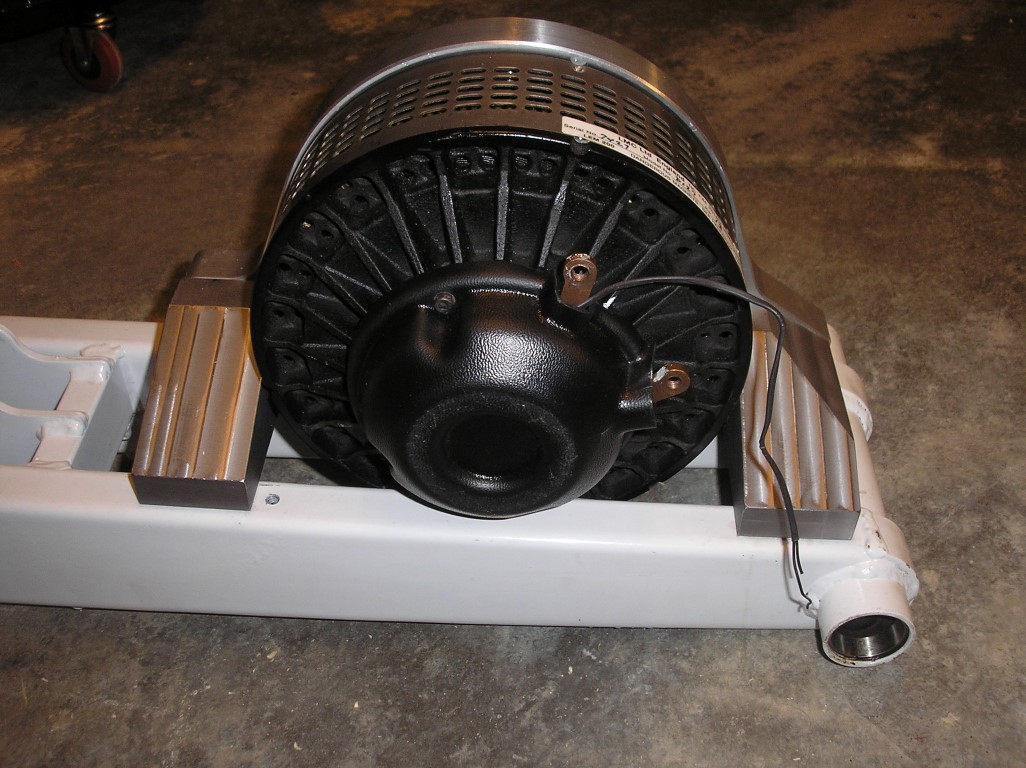

Good news after today! The motor is finally attached to the rear swingarm. The blocks were TIG welded onto it and it looks very nice. The welder also said that this weld would never crack. And even if it did, I could return to him and he'd repair it for free. So I think it's safe to say that it's definately sturdy enough. He did say though that the original welds on the rear swingarm weren't so great and those could crack some day, but well it's a Chinese quad bike so you never know what to expect.

Here are some pictures.

On the bottom the rear block was welded entirely as well, only the front block is welded about halfway since he couldn't reach it that well. But it's sturdy enough anyway. Don't really expect to ever get any problems with this.

I also attached the rear swingarm with motor back to the frame again. And then I came to the conclusion I was very lucky with the welding. Between the motor and suspension is only about 2 mm of space. Thought I'd have a lot more space there. But I'm in luck, it's just enough. And when the suspension compresses the space only gets bigger so no problems with that either. This way I only have more space to place the charger and the batteries so it's all good.

Now to wait for the adaptor and sprockets.

When I wanted to attach the rear swingarm to the frame again I suddenly saw some brake fluid on the floor. The hose between reservoir and brake pump was all wet. So I removed it to take a look. It's very small rubber en apparently not really resistant to dot 5.1 brake fluid. For now I replaced it with a fuel hose but I'll have to get something else for this.

Posted on 20 May 2013 at 10:51 pm (CET)

Category: Electric motor, Frame

Posted on 20 May 2013 at 10:51 pm (CET)

Category: Electric motor, Frame

Today I removed the paint of the rear swingarm on the spots where the blocks will be welded and the mount will be sitting. Did this with a steel brush drill bit, went pretty good.

Tomorrow hopefully a picture with the motor finally attached on there. I will probably also get the adaptor and sprockets this week.

Posted on 17 May 2013 at 09:47 pm (CET)

Category: Electric motor, Parts

Posted on 17 May 2013 at 09:47 pm (CET)

Category: Electric motor, Parts

Today I got the motor mount and the blocks back. The adaptor and sprockets aren't ready yet, will probably still take another week.

Everything fits well now and both of the blocks are now sloped which looks a lot nicer than such boring straight blocks.

Only a small problem because of the bad welding by the Chinese. On the rear there's quite some play between the blocks and the swingarm. On one block it's around 0,3mm and on the other 0,7-0,9mm. Wonder if this really matters to get it welded properly or if I'd have to add very small plates inbetween.

In any case I already contacted a welder nearby, going to wait and see what he says about it.

Nederlands

Nederlands